-40%

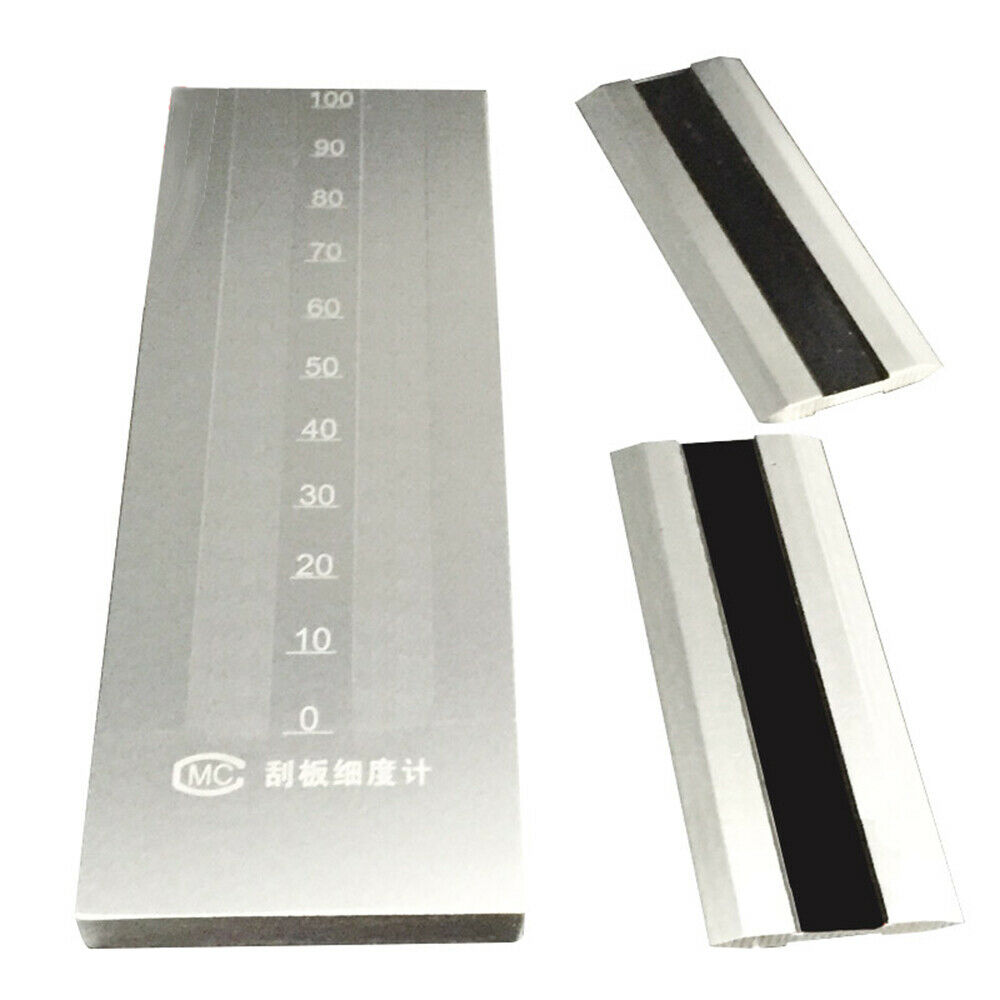

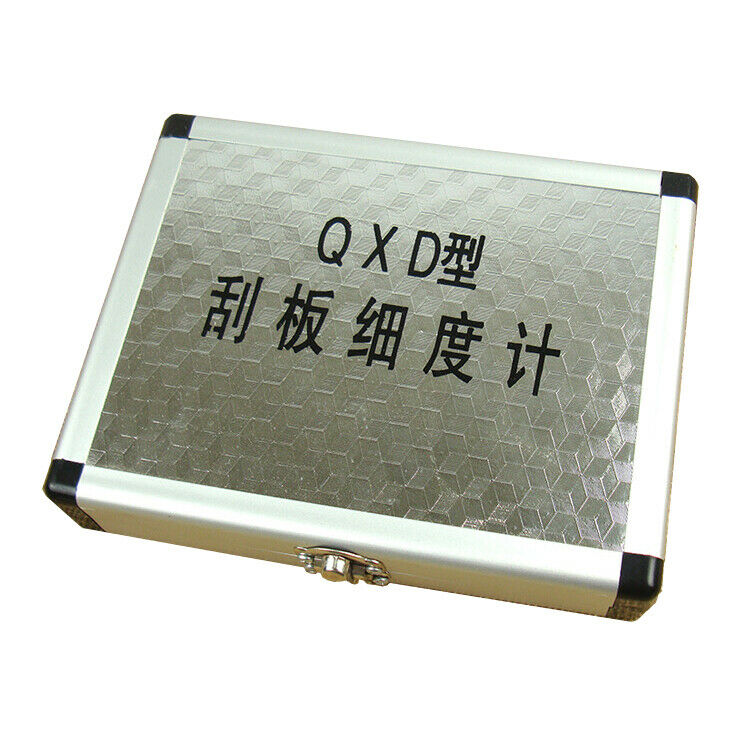

Double Groove Grindometer Fineness Grind Gauge Stainless Steel Scraper

$ 68.9

- Description

- Size Guide

Description

Double Groove Grindometer Fineness Grind Gauge Stainless Steel ScraperDescription QXD scraper fineness meter:

Technical parameters: the implementation of standards; GB/T1724-89

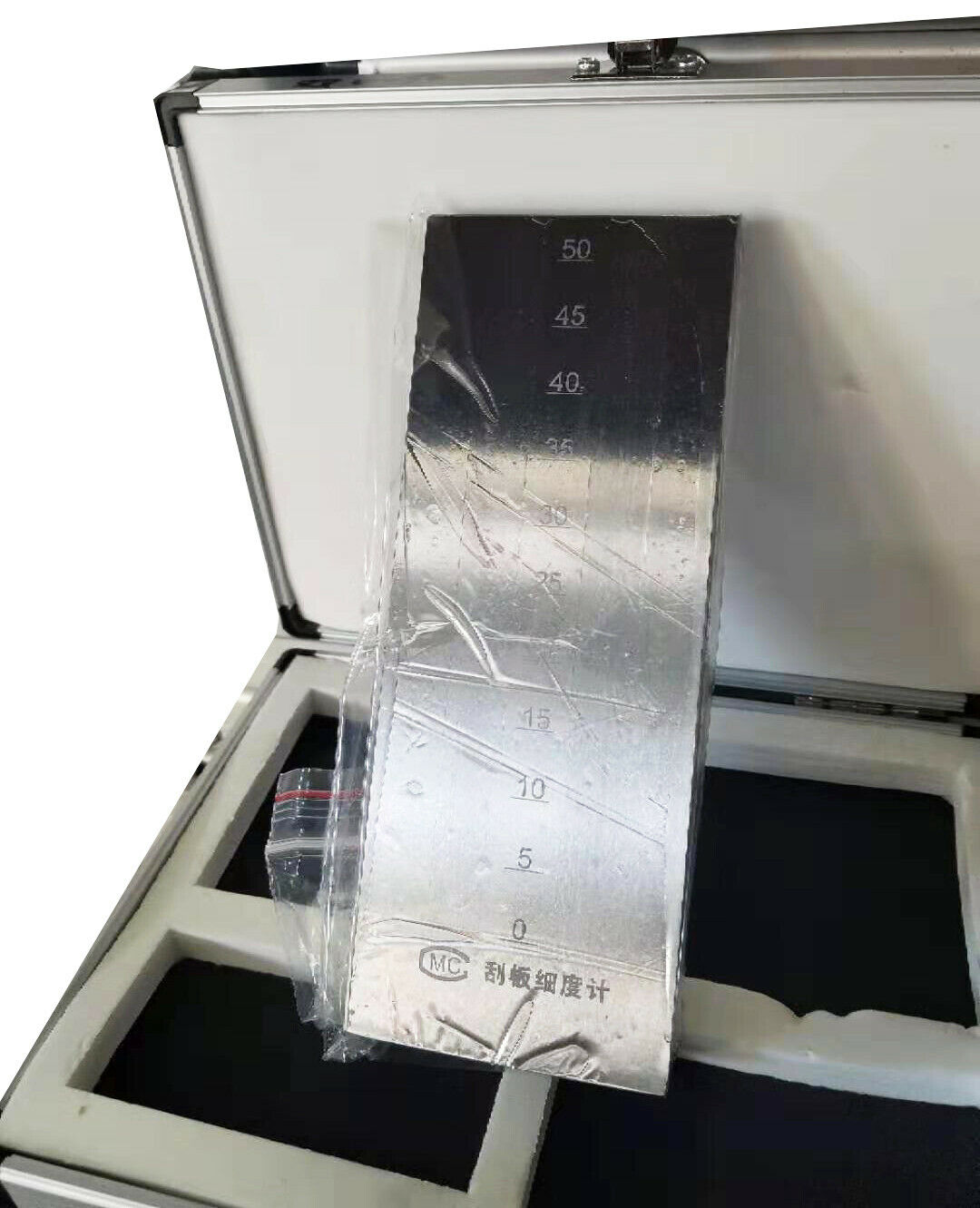

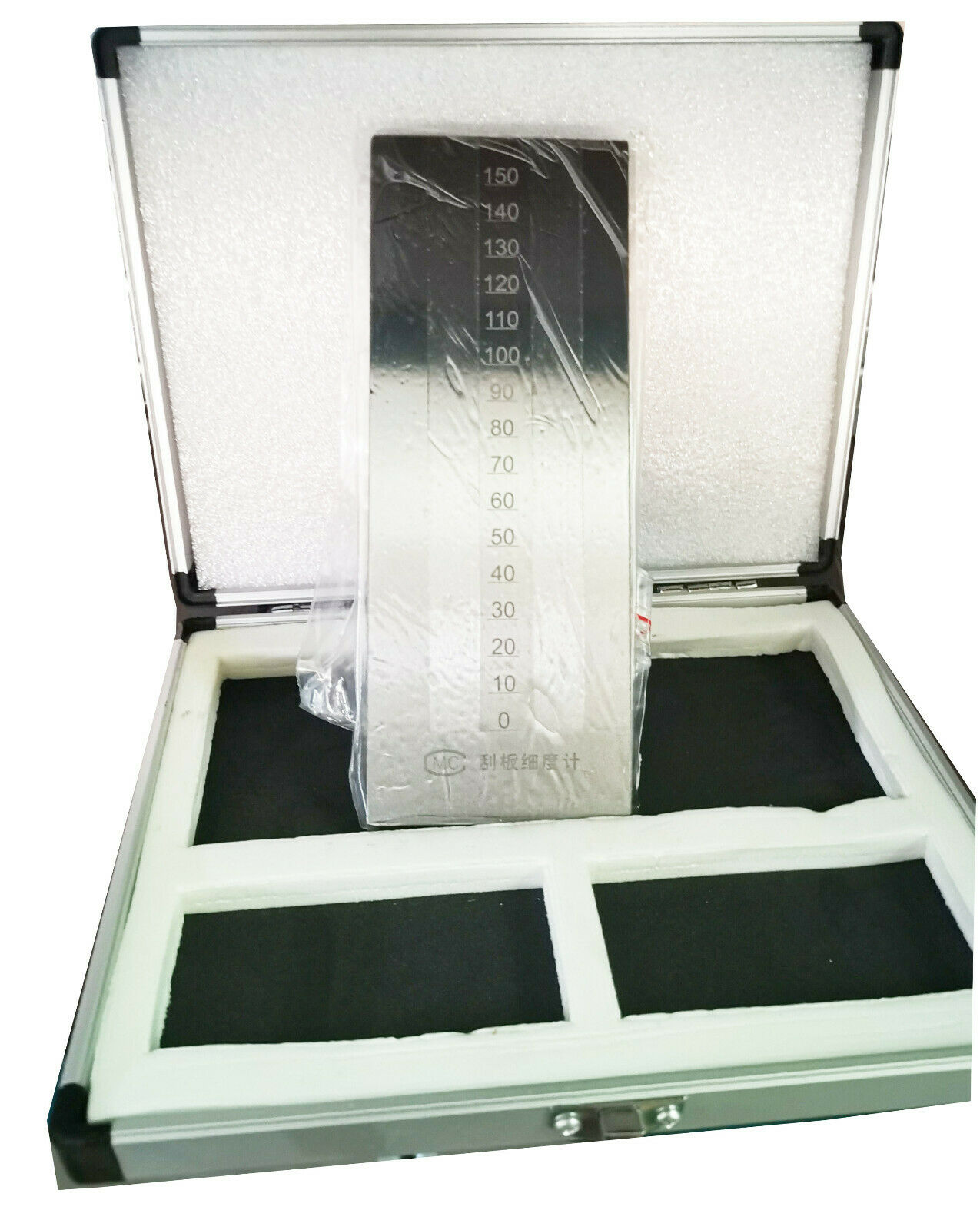

Range: 0-25, 0-50, 0-100, 0-150

Minimum division value: (2.5, 5, 10, 10)mm

Structure size: QXD scraper 155 * 50 * 12mm

Material: Cr12 molybdenum vanadium / high quality stainless steel

Product introduction

Fineness board for the production, storage and application of dispersed products in the process of fineness testing, such as applied to: paint, plastic, paint, printing ink, paper, ceramics, medicine, food, etc..

purpose

Fineness dispersion meter using the national steel (molybdenum vanadium) specified this product with stainless steel, used for the determination of pigment and impurity particles coating, paint paste, ink and other liquid and slurry size and dispersion degree, so as to control the quality of the products should be dispersed in the production, storage and use, such as paint, plastic, paint, printing ink, paper, ceramics, medicine, food and other fields.

Operation method

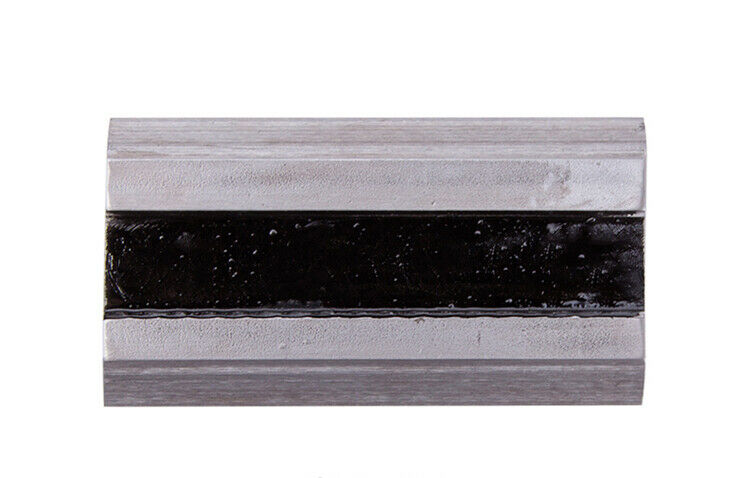

The test details refer to the current version of the British standard BS3900C6, the international standard ISO1524, the ASTM-D 1210 standard and some other domestic standards. The term "grinding fineness" is defined as the reading on the fineness plate under certain test conditions, which indicates the depth of the abrasive particles dispersed in the case of the solid particles. The abrasive particles used must be clean and dry, placed on the flat surface. The test activities as a test material is poured into the bottom of the groove, the hands holding the blade by the right angle, speed and smooth vertical pressure to the fineness of plate blade with enough downward pressure to clean the surface of grinding the particles at the same time, the groove is filled with particles. Through the observation of the fineness of plate, at the right angle and scraping angle, the determination of fineness of grind down immediately. Note that when the raw material grooves along the first time showed a significant surface punctate moment, down in the groove width of 3mm, the number of particles in the scale between 5 and 10. The high degree of numerical moment as grinding fineness, regardless of when the spots began to appear on the surface, scattered spots in any zone the clean immediately after the fineness of plate.

Repair and maintenance

1, the scraper surface and scraper crossing shall not bump.

2, after the use of washed and coated with anti rust oil.

3, a year, regularly check the scraper blade straightness, does not meet the standards should be timely repair.

4, the instrument is applicable to room temperature 22 + 1℃, the relative humidity of 70% conditions to ensure accuracy.